Main Second Level Navigation

Breadcrumbs

- Home

- News & Events

- Recent News

- Why the U.S. Department of Defense awarded a Toronto company a $356 million contract

Why the U.S. Department of Defense awarded a Toronto company a $356 million contract

Thornhill Medical, a company founded by two researchers based at University Health Network and the University of Toronto, recently received a contract to provide innovative anesthesia and life-support equipment to the U.S. military.

The $356 million contract, awarded in January through the Canada Commercial Corporation, will see Thornhill Medical outfit the U.S. armed forces with two compact medical devices designed for the battlefield: a life-support ventilator and oxygen concentrator, and a gas anesthesia vaporizer.

“There is a lot of pride in this achievement. It represents the confidence both the Canadian and U.S. governments have in our products and company and continues our journey into a major worldwide medical device provider,” says Joseph Fisher, co-founder of Thornhill Medical and professor emeritus in the department of anesthesiology & pain medicine at U of T’s Temerty Faculty of Medicine.

The story of how Fisher and Ludwik Fedorko — the other co-founder of Thornhill Medical, who is a clinician-scientist at UHN and an associate professor of anesthesiology & pain medicine at U of T — came to supply ground-breaking technology to the U.S. military begins with a surprise visit to Fisher’s UHN lab in 2001.

That visit was by Tom “Tommy” Eagles, a high-profile U.S. Navy medical corpsman, who had been referred to Fisher by a mutual friend working at Defense Research and Development Canada. Eagles had come to discover whether Fisher’s research could eliminate the need to carry oxygen tanks onto the battlefield.

“Oxygen tanks are heavy, bulky, and costly to transport and store. They hold limited oxygen and can be explosive. Tommy investigated me and my lab’s work and thought, ‘This just might work,’” says Fisher, a staff anesthesiologist at UHN and emeritus scientist at Toronto General Hospital Research Institute.

For several months after, Eagles toured military installations and headquarters around the U.S. with Fisher to float Fisher’s idea. About two years later, Fisher secured a contract and funding from the U.S. Marine Corps Systems Command to provide proofs of concept for the proposal.

Fisher’s task was to demonstrate the feasibility of converting small flows of oxygen from commercially available, bottle-sized ‘oxygen concentrators’ to provide the high lung oxygen concentrations to hyperventilating wounded soldiers, for the duration of their evacuation.

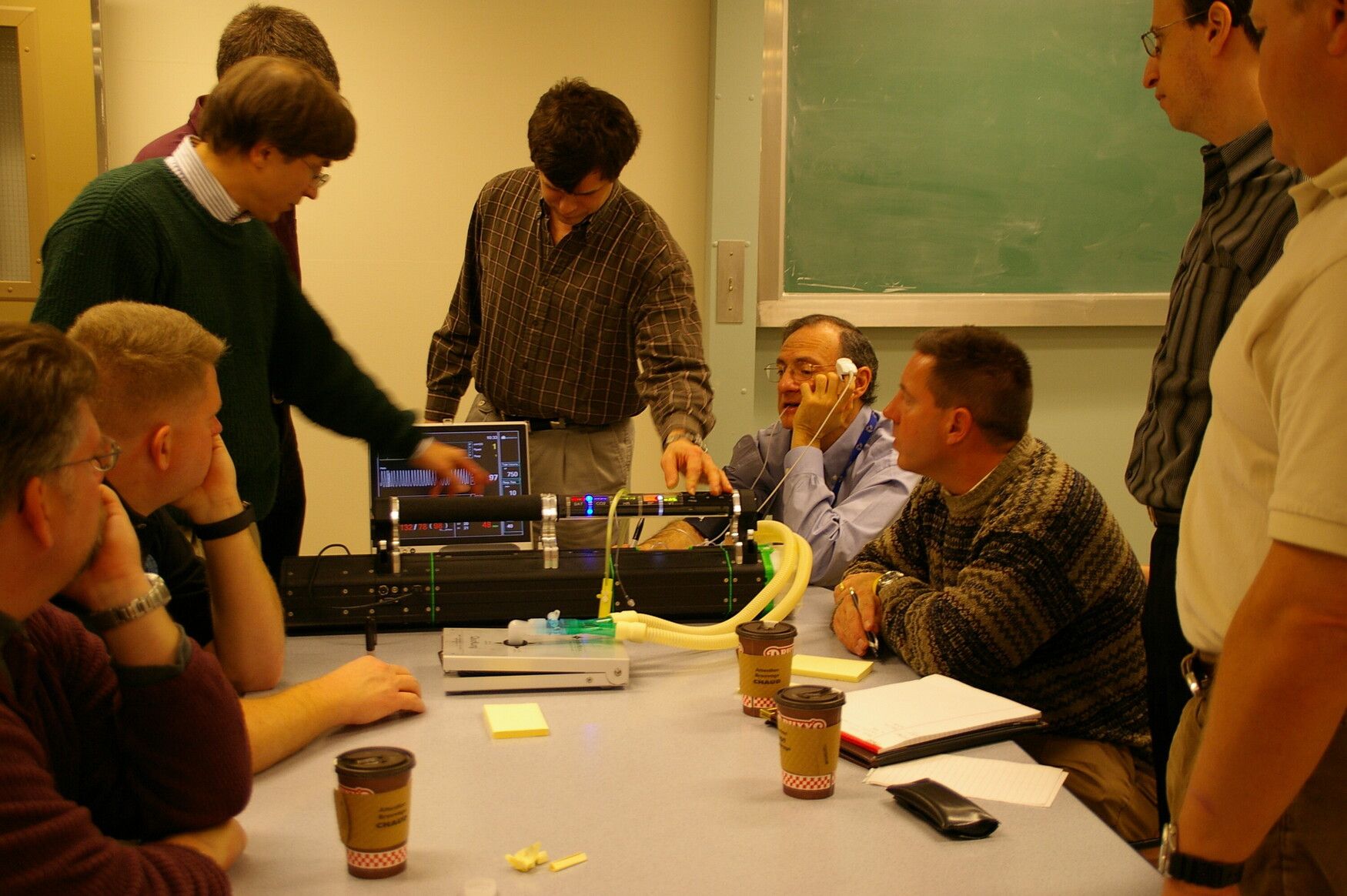

With the initial funding, Fisher and Fedorko created Thornhill Research Inc. — later Thornhill Medical — as a spinoff company from UHN in 2004. They hired a team of research students, engineers, and Cliff Ansel as CEO. They quickly outgrew their hospital lab, and in 2006 moved out of the hospital to a more industrial location.

“Well, we did finally get rid of the oxygen tanks, as Tommy asked,” notes Fisher. “We ended up taking the oxygen from the air, providing full ICU-type monitoring, suction, graphical interfaces, remote access, and an ICU-grade ventilator — all in a 20-kilogram portable unit running on batteries.”

The device that would become the MOVES SLC was born, but it needed the approval of government regulatory bodies before it could be launched, said Fisher.

A series of extensive military tests for ruggedness ensued.

The tests ensured the device would withstand various and severe stresses the MOVES SLC could face on battlefields. The United States Food and Drug Administration also required tests to certify the device.

“To say the least, this was a very tense and busy time where each test failure required substantial redesigns of multiple components and retesting of all previously passed tests,” says Fisher. After ethics board approval, the MOVES SLC underwent further testing in the provision of care to patients after cardiac and thoracic surgery at Toronto General Hospital.

“Eventually, we achieved the certification of the MOVES SLC, followed by its deployment on battlefields around the world where it is enjoying extraordinary success,” says Fisher.

A 2014 letter from Marine Corps Brigadier General Frank Kelly underscores the impact of the MOVES SLC, which was then called the Portal Patient Transport Life Support System. Kelly thanked the Thornhill Medical team for their excellent work on the life support systems, noting that the systems had “greatly improved the care provided to [the Marines’] forward deployed war fighters, thereby increasing their chances of survival on the battlefield.”

In the past, the medical equipment used by the military was often a generation behind that available to civilians. In the case of the MOVES SLC, personnel have access to the most advanced life support, says Fisher.

Today, the MOVES SLC is the only micro-integrated, life-support system that combines an internal O2concentrator, a unique O2-conserving ventilator, suction, and complete vital signs monitoring in a single compact, rugged, portable, battery-operated unit.

Thornhill has since launched a companion anesthesia product called MADM. It is a digital anesthesia delivery system the size of a two-slice toaster. Both pieces of equipment will be supplied to the various branches of the U.S. military under the new contract.

The company is now widely recognized as a leader in the precise control and management of arterial blood gases, and its technology also played a role in Canada’s fight against COVID-19.

Looking ahead, Fisher believes his blood gas control system can be a game changer for civilian medics and emergency personnel working in pandemics, and in natural or manmade disasters and other emergencies where oxygen levels can suddenly drop.

“Canada is a large country with many remote areas. The MOVES SLC in a remote clinic with only a stretcher can immediately be turned into an ICU. MADM will make emergency surgery possible in any sheltered place, even in the field,” says Fisher.

Today, Thornhill Medical holds over 40 patents, both awarded and pending, on various medical devices. Despite his successes, Fisher still values the innate curiosity and “why not” attitude that he says first inspired him to pursue medicine as a career.

“I have always been interested in science and research. Even during my undergraduate degree and medical school, learning about physiology, physics, and engineering fascinated me,” he says.

As a medical resident, Fisher worked as a research fellow under William Noble at St. Michael’s Hospital, a period that he considers one of the most exciting times of his life.

Later, as a physician, he mentored many aspiring physicians interested in performing research. He urges young physicians and researchers not to focus on the chances of “success.” Rather, they should celebrate the thrill of the search. Fisher’s personal mantra is: “It’s not the destination, it’s the journey.”

To those who want to follow his path to success, he advises, “If you are prepared to not succeed, you are free to follow the paths that are most interesting, and least travelled. And if you succeed nonetheless, the path followed will doubtless have contributed much to the novelty of the solution.”

News